- Network of farms, market and auctions allow us

to source best quality product

- Strict quality control at point of purchase

- Our 7 graders sort goods into different sizes,and

are specially engineered to handle delicate

Indian onion skins

- Quality control team inspect conveyers and

remove interior bulbs

- The various sizes 30/40, 40/50,50,70,60/80 etc

are collected in wooden boxes (precured from Poland) and

stored to be used later for packing line

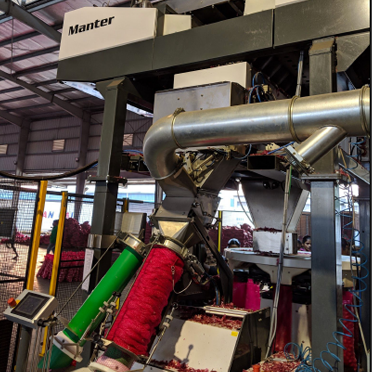

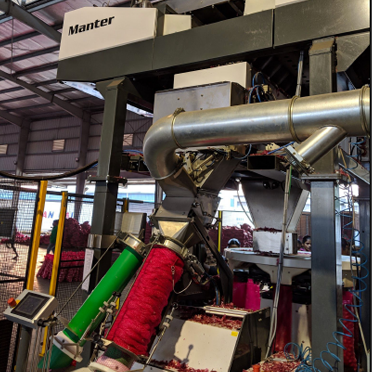

- MANTER machines ensured precision weighing

and fast packaging of product into bags of

different sizes and materials

- Clipper machines used to pack supermarket

ready bags

- Manual labor used to pack orders of 50+Kg into

jute bags

- Labels and barcodes are affixed onto bags as per

custumers request

- The lnward and arrivals of the

product, are subject to weighing on

our inhouse weigh bridge is taken for sampling.

- After a propper assessment and approval of samples,

the product is unloaded.

- Tier 2 AED (Authorized Economic Operator)

from Mumbai Customs- Under Process

- In- house self-sealing of containers

- Refrigerated (Reefer) containers used to ensurve

longevity of perishable Product

- Administration and Operations are managed

under one roof: Our team manages

documentation,customs,phytosanitary certifications etc.

Our MANTER Carouel can pack 5kg to 10kg bags

Our precision clipper prepacks 500gms to 3 kg with/withour labels.

Forklifts used for speedy transportation around packaging plant

Specially deigned wooden boxes used Weighbridge for long-term storage and efficient technology product size management

Regular quality control inspections

Network of international logistics providers and shippers